Structural Steel Detailing Case Study

SUMMARY OF THE PROJECT

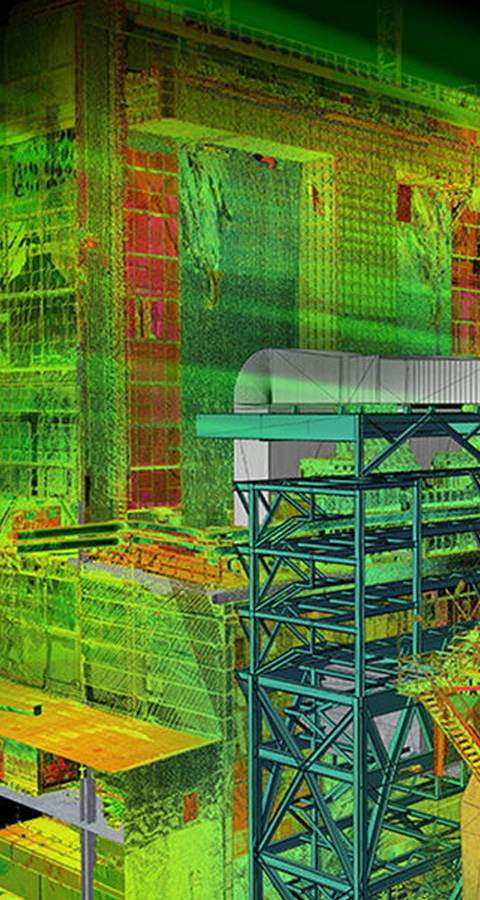

Clove Technology recently concluded a Prestigious “Structural Steel Drafting” Project using Tekla. Creation of an Integrated and accurate shop drawing along with delivering High return on investment on the project not only during the construction stage

but throughout the lifetime of the Asset which forms the core ethos of a successful Project.

The whole team was always on the same page to execute the exact structure drawings

intended to everyone (client, structural engineers, managers, etc).

WHAT WAS DONE?

The Scope entailed as mentioned below:

Our technical teams of engineers, architects and drafters delivered drawings for prefabricating building products and elements to enable offsite construction efficiency and reduce safety risk.

The team works

in tandem with the client organization as though an extension of the client’s team.

OUR SCOPE OF WORKS

RE-BAR DETAILING IN TEKLA

ASSEMBLY DRAWINGS

COLD ROLLED PRODUCTS w/ NC FILES

PLATES DRAWING

BOLT & FIXING LIST

INDIVIDUAL PARTS

STORCO STANDARD BRACETS

PROJECT INFORMATION

Client A Leading consultant in engineering services

Location NSW, Australia

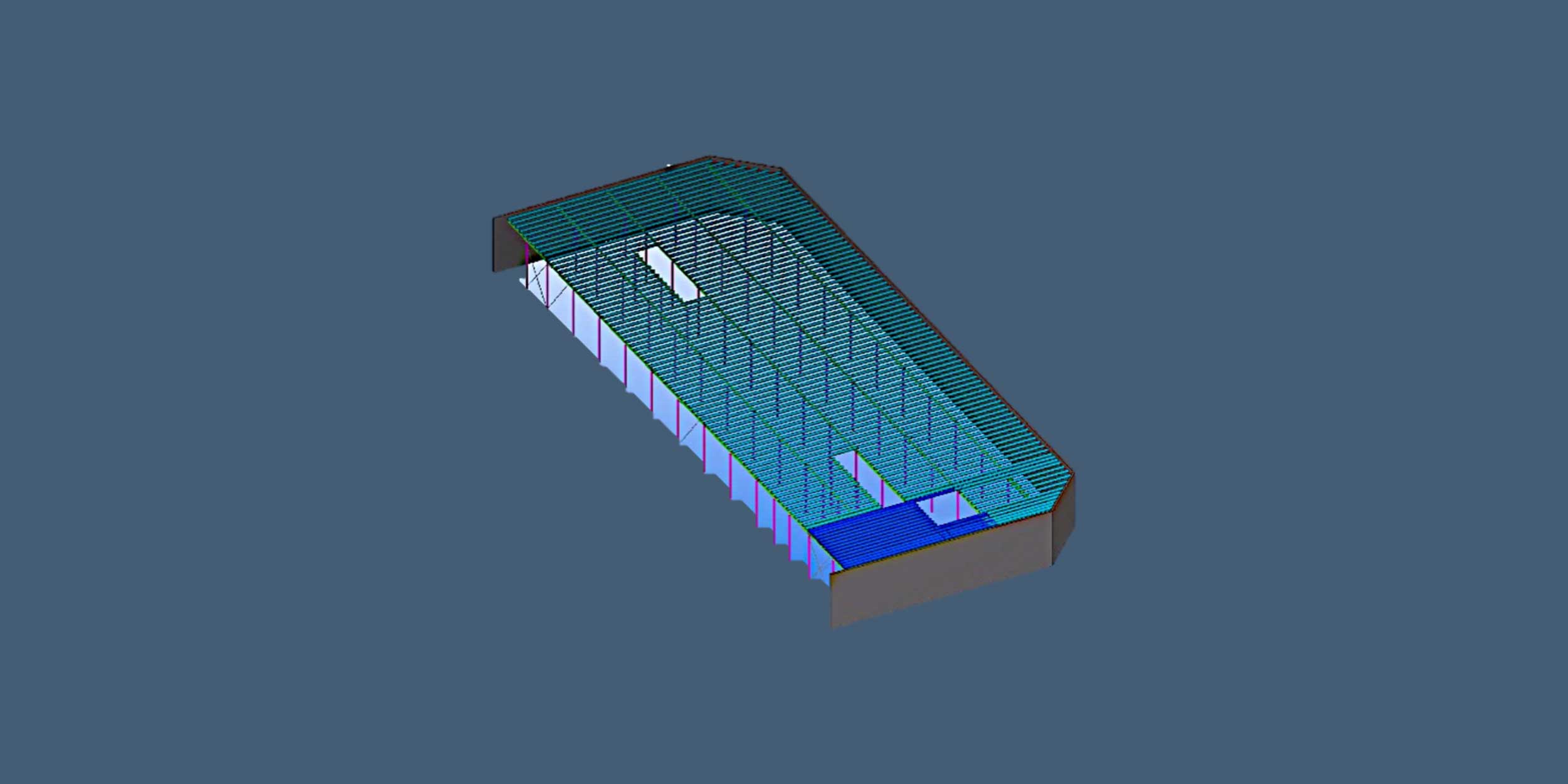

Project Storage Facility

Project Type Structural Steel drawings

Project Commenced May 2019

Software Used Tekla, AutoCAD 2019

What were the key Outcomes?

- Reduced errors and coordinated design reliably.

- Generated construction documentation easily from the model.

- Accommodated design changes painlessly.

- Delivered accurate structural drawings to contractors.

- Generated shop drawings incorporating complete fabrication and installation of all components, to be utilized by specific trade contractors and fabricators.

- Building elements are modelled as specific assemblies with complete fabrication, compilation, installation and detailed reports in addition to precise quantity, size, shape, location, and orientation.

- The delivery of drawing products was completed in 5-6 weeks.

CHALLENGES

- Structure had been complex to analyze for the production in short duration.

- The technical team initially faced issues while receiving inputs and had to tackle technical issues but with their domain expertise they successfully overcame the hurdle.

- Quick delivery Time was another hurdle for the team.

- Quality Checking in shortage of time was established parallelly to the production.

- Communication is another challenging task since it is an outsourcing project.

KEY LEARNINGS

- Client was able to save time and money through effective construction practices.

- Quick and effective response to cater the client needs.

- Allocation of expert drafting team.

- CDE Model implementation where all stakeholders exchange project information

- Quality Check on each output that is delivered to the client.

KEY TAKE-AWAY

It is important to understand current work processes and practices Look to implement quick wins to leverage buy-in from employees. Do not try and change everything at once. Put metrics in place to measure success of implementation