Unexpected equipment failures are costly, disruptive, and often avoidable. Unfortunately, many industries still rely on traditional maintenance methods that react only after a breakdown or follow fixed schedules, regardless of the asset’s actual condition.

As a result, companies waste valuable time, resources, and productivity.

However, what if you could predict exactly when your equipment needs maintenance before any damage occurs? Instead of reacting to failures, you could act in advance, saving both time and money.

This is where Clove Technologies steps in. Using advanced Digital Reality services combined with high-precision point cloud data, we help businesses shift from reactive to predictive maintenance. Our technology monitors asset conditions in real time, detects potential issues early, and delivers insights you can act on.

With Clove Technologies, there is no guesswork and no costly surprises just smarter maintenance decisions powered by reliable data.

Many industries still rely on conventional maintenance methods that are:

- Reactive – Repairs only happen after a failure occurs

- Time-based – Maintenance follows a fixed schedule, not actual asset condition

- Costly – Emergency repairs and downtime quickly add up

Modern operations demand smarter, real-time insights. That’s where Clove Technologies leads the way.

Explore more on our Digital Reality Services page.

Clove Technologies collects high-resolution spatial data through cutting-edge scanning tools:

3D Laser Scanning

- Delivers sub-millimeter accuracy

- Detects wear, cracks

- Detects misalignment early

Drone Surveys with LiDAR & Photogrammetry

- Captures aerial data quickly and safely

- Ideal for large

- Ideal for hard-to-reach assets

Ground Penetrating Radar (GPR)

- Reveals underground structures

- Reveals voids, or unstable foundations

These tools generate rich point cloud data, forming the basis for predictive intelligence.

Learn more about Point Cloud Processing and its industry applications.

Clove transforms raw scans into real-time asset health insights:

Step 1: Digital Twin Creation

A high-fidelity 3D model is built from initial scans, establishing a digital baseline.

Step 2: Ongoing Monitoring

Routine scans detect even subtle changes like corrosion, deformation, or structural shifts.

Step 3: Automated Alerts

Alerts are triggered when anomalies are detected, preventing failures proactively.

Step 4: Integrated Predictive Modeling

We enhance scan data with:

- Sensor outputs

- Maintenance records

- Usage patterns

This integrated system helps forecast failures and optimize scheduling.

Also read: What is Predictive Maintenance? by IBM

| Feature | Traditional Maintenance | Predictive Maintenance (Clove) |

|---|---|---|

| Method | Time or failure-based | Condition-based and proactive |

| Insight | Low | High (via 3D and sensor data) |

| Cost | High (reactive repairs) | Lower (targeted interventions) |

| Risk | High | Reduced through early alerts |

| Downtime | Unpredictable | Planned and minimal |

If your operations depend on uptime and safety, predictive maintenance gives you a competitive edge:

At a major thermal power plant, Clove Technologies helped reduce unplanned shutdowns by 45%. Our 3D laser scans revealed turbine casing shifts weeks before critical failure. Early intervention saved time, cost, and reputation.

For more success stories, check our Case Studies.

Q1: How precise is 3D laser scanning?

Ans: Our scanners detect changes as small as a millimeter, giving you unmatched detail.

Q2: How often should scans be conducted?

Ans: Typically quarterly, but frequency depends on your asset’s risk profile.

Q3: Can this connect with my current systems?

Ans: Yes. Our models integrate with most CMMS and asset management platforms.

Want to see how predictive maintenance works in real life? Embed video walkthroughs, interactive 3D models, or before/after scan comparisons to understand the transformation.

Check out our YouTube channel for demos.

Partner with Clove Technologies to move from reactive maintenance to proactive performance. We provide:

- High-accuracy asset scans

- Digital twins for monitoring

- Predictive data integration

- Custom strategies for your sector

Stop reacting. Start predicting.

Explore our Infra Services for large-scale industrial solutions.

Discover more of our innovative blogs

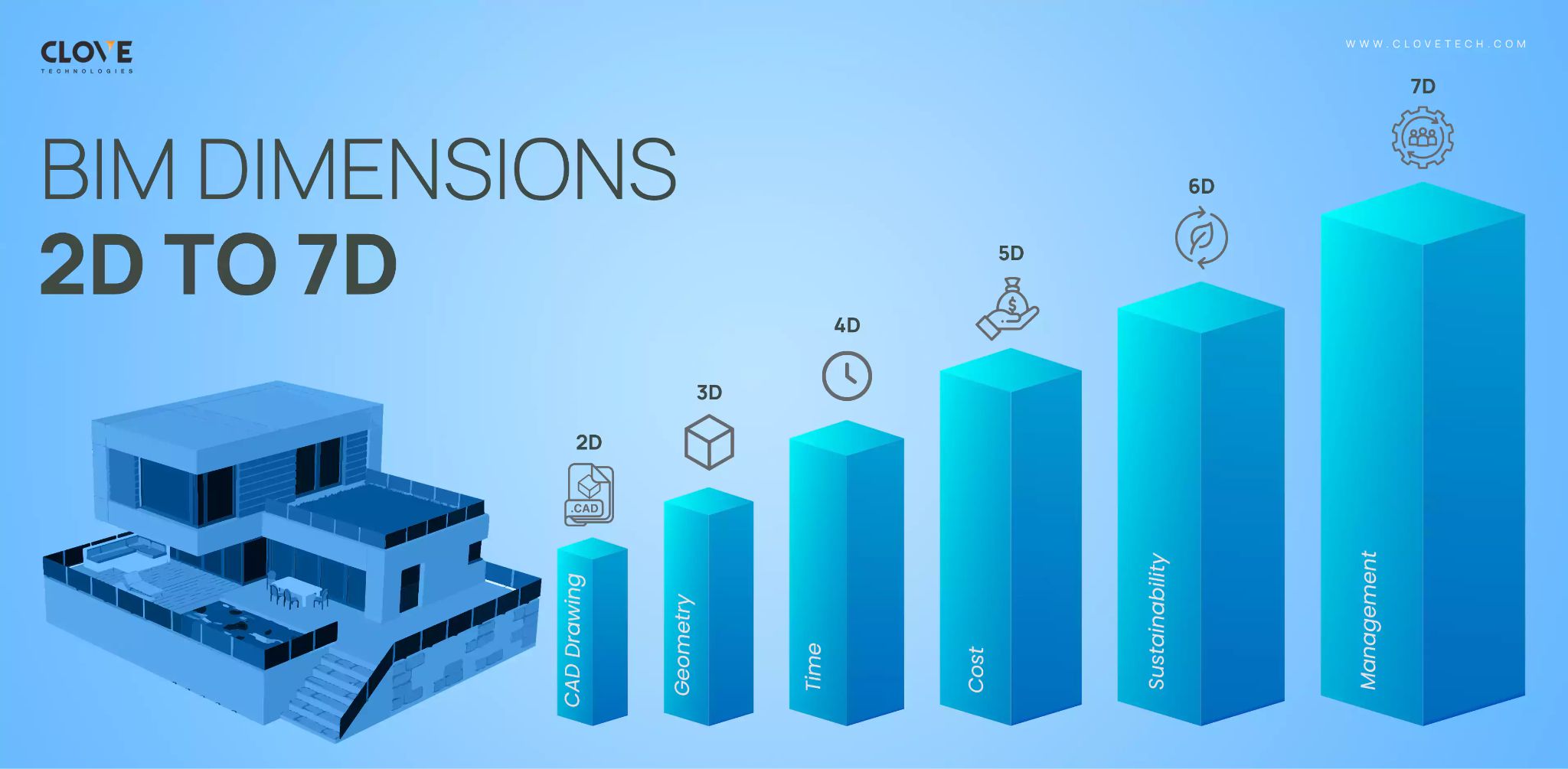

Understanding BIM deviations and how to minimize them

AI for feature engineering: How to extract meaningful data

CloveTech’s Commitment to Quality Recognized with ISO 19650 Certification

A Complete Guide to the 2D–7D Evolution of BIM

Let's Talk

Let’s discuss your requirements and see how our expertise can help on your next project.